Product Description

| Introduction In the world of semiconductor wet processes, precision and efficiency are paramount. CPH-P38-180/220-15-A T200 N2 Heater is not only designed for post-cleaning drying tasks but also serves as a replacement for traditional immersion heaters and heater-wrapped tubes in thermal systems. By adopting our advanced heater, users can significantly reduce system cost and complexity. Due to its high watt density, the N2 Heater ensures faster response and superior performance, making it an ideal solution for rapid wafer drying and rotating IPA drying processes. | |

Key Applications 1. Clean Heating: Harness the power of high-purity N2 for impeccable gas heating, ensuring the utmost in clean heating characteristics. 2. Semiconductor Excellence: Elevate your semiconductor, liquid crystal, and organic EL manufacturing equipment with inert gas heating. 3. Analytical Precision: Achieve precise heating for high-purity gases, perfect for analyzers and small-scale testing equipment. 4. Simulation Mastery: Explore gas heating for combustion gas simulation experiments, pushing the boundaries of your research. 5. Chemical Production: Optimize the production process of chemical materials with controlled gas heating. 6. Versatile Heat Treatment: In the realm of heat treatment, rely on atmosphere gas heating in your heating furnace. | ||

Product Specifications

Model: | CPH-P38-180/220-15-A T200 | |

Material: | Substrate Tube Material: | Electropolished 304 stainless steel |

Performance Parameters: | Voltage: | 220V/50Hz |

| Power: | 1300-1400W (+5%/-10%) | |

| Amperage: | Up to 7A per zone | |

| Gas Pressure: | 0.3-0.6MP | |

| Flow Rate: | 50-200L/min | |

| Output Temperature: | 25-200℃ | |

| Typical Maximum Watt Densities: | ||

| Air: | 22 W/cm2 | |

| Water: | 60 W/cm2 | |

| Maximum Pressure: | 5~6 bar | |

| Maximum Temperature: | 200°C (as measured) | |

Dimensions: | Outer Diameter: | Φ38mm |

| Body Length: | 180mm | |

| Pipe Diameter: | A-1/2 B-3/8 C-1/4 | |

Orientation: | Gas Heating: | Can be in any orientation (vertical or horizontal) |

| Liquid Heating: | Can be in any orientation (vertical or horizontal) | |

Elegant Design This N2 Heater boasts a sleek stainless steel mounting base and a protective stainless steel cover, ensuring durability and a professional appearance. | Cutting-Edge Features - Utilizes a state-of-the-art thick film heating tube for rapid and efficient heating. - Enhanced safety with an over-temperature protection probe and a K-type thermocouple with a recommended protection value set at 200°C. - Features a protective tube, threaded guide channel, and dual support bases for secure installation. - Precision control is at your fingertips with a gas pressure regulating valve, gas throttle valve, gas flow meter, gas flow monitoring, over-temperature protection detection, outlet temperature detection, load output, and a temperature control power adjustment module. |

System Performance Maximization CPH-P38-180/220-15-A T200 N2 Heater is designed to maximize system performance. Emphasizing the benefits of its design and high watt density, it ensures optimal efficiency and response times, aligning with the highest standards in the industry. | |

Innovative Printing Technology CPH-P38-180/220-15-A T200 N2 Heater utilizes Printing Technology to makes use of its entire surface to produce heat and optimizes heat transfer and temperature uniformity. | Precautions for Use - Ensure reliable grounding for safe operation. - Avoid dry burning by utilizing electronic control, including over-temperature protection and flow sensor integration. |

User-Friendly Control Adjust the outlet temperature with ease through the power adjustment module on the user side, with a maximum temperature cap set at 200°C. |

Discover the future of high-performance gas heating with CPH-P38-180/220-15-A T200 N2 Heater. Elevate your processes, enhance precision, and experience the pinnacle of efficiency.

Product Advantage

Optimizing Semiconductor Manufacturing with Controlled Nitrogen Atmospheres

Semiconductors have been the backbone of modern technology, and ensuring their precision manufacturing demands specialized solutions. Over time, manufacturers and semiconductor producers have harnessed the power of nitrogen to enhance their processes. Whether it's in the production of stacked dies, rework procedures, or component solder bumping, nitrogen gas has proven invaluable. It creates a controlled environment, widening the process window while maintaining minimal oxygen levels.

With the shift towards mandated lead-free soldering, the industry faces new challenges, particularly regarding flux chemistry aggressiveness and the need for tighter temperature control (Delta T). Here, nitrogen (N2) inerting emerges as a key factor in boosting production success.

Controlled nitrogen atmospheres play a pivotal role in various on-ground manufacturing applications, such as reflow, wave soldering, selective soldering, and rework. These controlled environments provide engineers with a broader scope to operate effectively. Nitrogen's benefits extend to the liquidous state, where it aids in surface wetting, ensuring strong and reliable bonds.

Semiconductor manufacturing is an intricate and precise process, demanding a constant supply of heated nitrogen for reliable solder lines. Compliance with lead-free soldering regulations is mandatory in the industry. This is where KRT nitrogen heaters shine, ensuring a consistent supply of heated nitrogen at manufacturing sites. High-purity nitrogen is a necessity for all semiconductor and assembly processes, including reflow, wave soldering, selection, and rework. The use of nitrogen heaters in creating a controlled atmosphere meets the exacting production parameters demanded by semiconductor manufacturing operations.

Benefits of Nitrogen Heaters:

Nitrogen heaters are tailored to meet the unique requirements of heating nitrogen, contributing to the efficiency and safety of on-ground manufacturing processes. Safety with Nitrogen Heaters:

KRT nitrogen heaters are meticulously designed to maintain a 100% dry environment. This is particularly critical since nitrogen is an inert gas used in processes where contact with water could lead to explosive situations. Moisture accumulation within tanks poses a risk, as vaporized chemicals can potentially contact water. The use of nitrogen heaters mitigates this risk effectively. Additionally, various housing options are available to enhance safety further.

Product Applications

Semiconductor Manufacturing: Nitrogen heaters are crucial in semiconductor manufacturing for processes such as reflow soldering, wave soldering, and selective soldering to ensure the production of high-quality electronic components. | Solar Photovoltaic Manufacturing: Nitrogen heaters play a role in the manufacturing of solar photovoltaic panels, ensuring precise production in this renewable energy sector. |

| Aerospace and Aviation:** Nitrogen heaters find applications in aerospace and aviation facilities for processes like inerting fuel tanks, preventing the risk of explosions in fuel storage and handling. | Oil and Gas: In the oil and gas industry, nitrogen heaters are used for various applications, including purging pipelines and tanks to prevent the formation of explosive mixtures and providing inert atmospheres during drilling operations. |

Electronics Assembly: They are used in electronics assembly lines to maintain the purity of nitrogen during the soldering of circuit boards and components, ensuring reliable connections. | Metal Processing: In metalworking and heat treatment industries, nitrogen heaters are used to create controlled atmospheres for processes like annealing, brazing, and sintering. |

Chemical and Pharmaceutical: Nitrogen heaters can be employed in chemical and pharmaceutical manufacturing processes, especially those that require an inert atmosphere, such as the production of chemicals, pharmaceutical ingredients, or sensitive compounds. | Laboratories: Laboratories often utilize nitrogen heaters for applications like gas chromatography, where a consistent and pure nitrogen supply is essential for accurate analytical results. |

| Chemical Reactions: Nitrogen heaters are employed in chemical research and industrial settings to maintain inert atmospheres during sensitive chemical reactions and experiments. |

FAQ

**Q1:** What is the primary purpose of the CPH-P38-180/220-15-A T200 N2 Heater?

**A1:** The primary purpose of the CPH-P38-180/220-15-A T200 N2 Heater is to serve as a replacement for traditional immersion heaters and heater-wrapped tubes in thermal systems while facilitating post-cleaning drying tasks. It is designed to enhance precision and efficiency in semiconductor wet processes.

**Q2:** What are the key applications of the CPH-P38-180/220-15-A T200 N2 Heater?

**A2:** The key applications of the CPH-P38-180/220-15-A T200 N2 Heater include clean heating with high-purity N2, elevating semiconductor manufacturing equipment with inert gas heating, achieving precise heating for analyzers and small-scale testing equipment, gas heating for combustion gas simulation experiments, optimizing chemical production processes with controlled gas heating, and using atmosphere gas heating in heat treatment.

**Q3:** What are the specifications of the CPH-P38-180/220-15-A T200 N2 Heater, including voltage, power, and temperature range?

**A3:** The CPH-P38-180/220-15-A T200 N2 Heater operates at a voltage of 220V/50Hz, with a power range of 1300-1400W (+5%/-10%), and it can reach an output temperature range of 25-200°C.

**Q4:** What are the maximum watt densities for air and water heating with this N2 Heater?

**A4:** The maximum watt densities for air and water heating with the CPH-P38-180/220-15-A T200 N2 Heater are 22 W/cm² for air and 60 W/cm² for water.

**Q5:** What are some of the cutting-edge features of the CPH-P38-180/220-15-A T200 N2 Heater?

**A5:** Some of the cutting-edge features include the utilization of a thick film heating tube for rapid and efficient heating, over-temperature protection, a K-type thermocouple for temperature monitoring, a protective tube, threaded guide channel, dual support bases for secure installation, and precision control components like gas pressure regulation, throttle valve, flow meter, and temperature control power adjustment module.

**Q6:** How is the N2 Heater designed to maximize system performance?

**A6:** The CPH-P38-180/220-15-A T200 N2 Heater is designed with a high watt density and various features aimed at maximizing system performance. It ensures optimal efficiency and response times, aligning with the highest industry standards.

**Q7:** How can users control the outlet temperature of the N2 Heater, and what is the maximum temperature cap?

**A7:** Users can adjust the outlet temperature of the N2 Heater with ease using the power adjustment module on the user side, and the maximum temperature cap is set at 200°C.

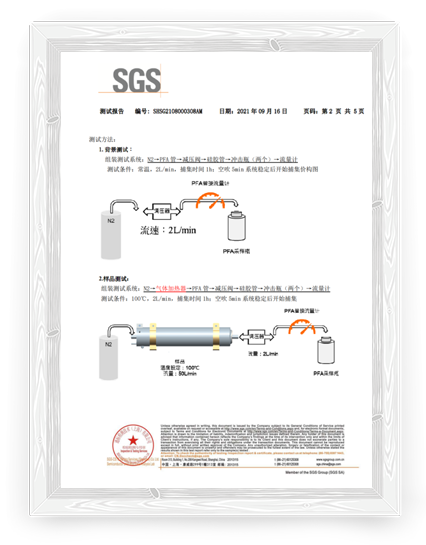

Certificate

|  |

|

|  |

|

Download