Product Description

|  |

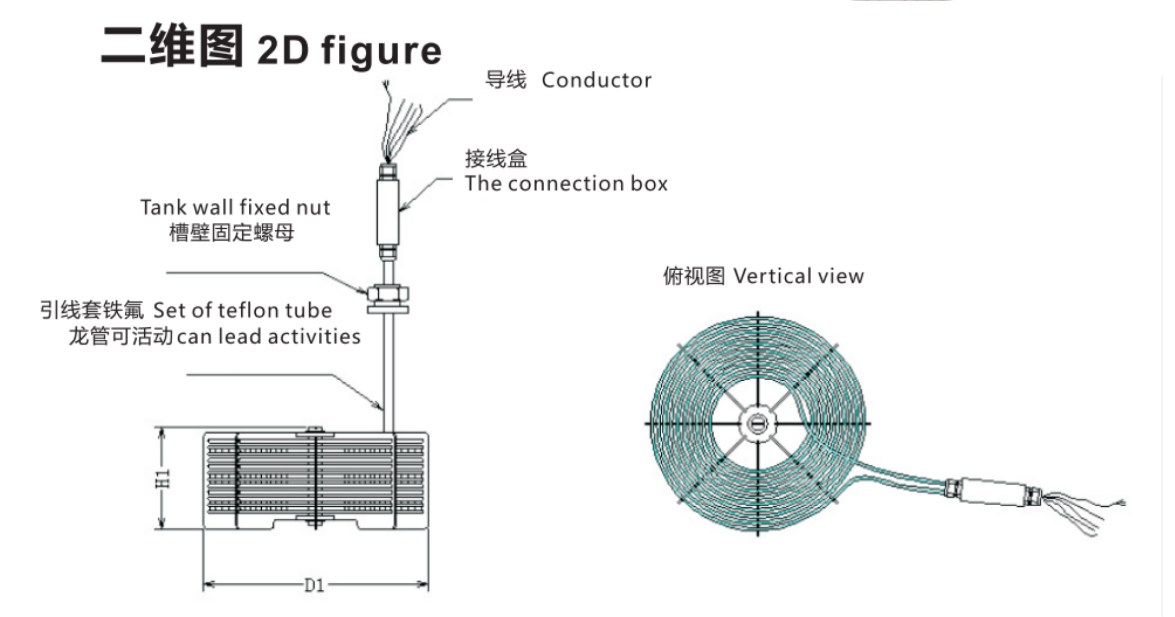

Product Introduction & Details

Introducing our premium Plate Type Teflon Heater, meticulously crafted with the following features:

1. Constructed using superior-grade heating wire direct packaging (CPTEF) combined with imported fluoroplastics. This ensures robust corrosion resistance, non-adhesiveness, and a commitment to energy efficiency and environmental sustainability. It is adept at heating a wide range of corrosive liquids.

2. The low surface power design is implemented to guarantee an extended product lifespan.

3. For enhanced durability and equipment safety, all our electric heaters come fitted with PT100 temperature probes or temperature fuses.

4. Experience energy efficiency at its best. Our heater offers a 20% energy saving when compared to heaters of equivalent power.

5. Our product proudly holds CE certification.

Product Advantage

Overview: A coiled shape Teflon immersion heater could be designed for applications where there is a need to heat corrosive liquids or where non-stick properties are essential. Industries such as chemical processing, laboratories, or certain water treatment applications might benefit from this type of immersion heater. Advantage: 1. Immersion Heater:

Immersion heaters are electric heating elements designed to be immersed in a fluid (usually a liquid) to heat it. They are commonly used in industrial, commercial, and residential applications for heating liquids like water, oil, or chemicals.

2. Coiled Shape:

The term "coiled shape" suggests that the heating element might be designed in a coiled or spiral form. Coiled shapes can provide efficient heat transfer and are often used in immersion heaters to maximize the heating surface area within a confined space.

3. Teflon Coating:

Teflon (PTFE) is a non-stick and chemically resistant material. Teflon coatings are often used in immersion heaters when the heated liquid may contain corrosive substances. The Teflon coating provides protection against chemical reactions and helps prevent the heating element from corroding.

Exploring the Advantages and Applications of PTFE

Polytetrafluoroethylene (PTFE) is an extraordinary polymeric material with a wide array of exceptional properties. This versatile elastomer exhibits remarkable chemical resistance, durability, flexibility, and impressive electrical and thermal resistance. Additionally, it offers a cost-effective solution for high-performance seals and 'O' rings. In this article, TRP Polymer Solutions introduces you to the world of PTFE, highlighting its various uses and remarkable properties.

Understanding PTFE

Polytetrafluoroethylene, commonly known as PTFE, is a resilient and flexible elastomer with an average tensile strength. What sets it apart is its extraordinary chemical resistance and exceptional thermal and electrical insulating properties. On a molecular level, PTFE consists of a chain of carbon atoms, each bonded to two fluorine atoms. These fluorine atoms envelop the carbon chain, creating a dense molecule with incredibly strong carbon-fluorine bonds. This unique polymer structure renders PTFE inert to the majority of chemicals.

Advantages of PTFE

PTFE derives its impressive qualities from the robust carbon-fluorine bonds, widely recognized as one of the strongest single bonds in organic chemistry. Here are some of the key advantages of PTFE:

Chemical Inertness: PTFE's exceptional chemical resistance makes it impervious to most solvents, ensuring its integrity even in corrosive environments.

Electrical Insulation: It offers excellent electrical insulation and high dielectric strength, making it a preferred choice in electrical applications.

Weather Resistance: PTFE is highly resistant to weathering and does not adhere easily to contaminants. It also exhibits water resistance.

High-Temperature Tolerance: With the ability to withstand temperatures ranging from -30°C to +200°C, PTFE remains stable in extreme thermal conditions.

Low Friction: PTFE boasts the lowest coefficient of friction among solid materials, reducing wear and friction-related issues.

Broad Operating Range: Its operational temperature range, hardness (70 to 85 IRHD), and ease of cleaning further enhance its utility.

Cost-Effective Sealing: Despite its remarkable qualities, PTFE remains a cost-effective choice for elastomeric seals and 'O' rings, though it does have a tendency to creep under compression. TRP Polymer Solutions addresses this challenge by incorporating a bonded rubber core to energize PTFE seals, enhancing their compression resistance.

Applications of PTFE

PTFE's unique properties open up a wide range of applications, including seals (including 'O' rings), gaskets, valves, wire insulation, insulated transformers, bearings, surface coatings, chemical processing equipment, chemical transport, and PTFE rubber diaphragms.

Chemical Resilience of PTFE

One of the most impressive characteristics of PTFE is its unparalleled chemical resistance. In essence, there are very few solvents capable of dissolving PTFE at room temperature. Its only significant vulnerability lies in its limited resistance to high-energy radiation, which can lead to the breakdown of PTFE molecules.

Product Applications

coiled shape Teflon immersion heater can find application in various industries and processes where the heating of corrosive liquids or substances is required. Here are some common applications:

Chemical Processing Industry: Coiled shape Teflon immersion heaters are often used in chemical processing to heat corrosive chemicals and liquids. The Teflon coating provides protection against chemical reactions, ensuring the longevity of the heating element. | Laboratories and Research Facilities: Laboratories and research facilities dealing with sensitive experiments or processes involving corrosive substances may use Teflon-coated immersion heaters. The non-stick properties of Teflon can be crucial in preventing contamination. |

Electroplating and Metal Finishing: Industries involved in electroplating or metal finishing often handle corrosive solutions. Coiled shape Teflon immersion heaters can be employed to maintain specific temperatures in these solutions for optimal processing. | Water Treatment Plants: In water treatment applications where the water being treated contains corrosive elements or chemicals, Teflon-coated immersion heaters can be used to heat the water for various treatment processes. |

Biotechnology and Pharmaceuticals: Laboratories and facilities in the biotechnology and pharmaceutical industries may use Teflon-coated immersion heaters for heating solutions and substances in processes where corrosion resistance is essential. | Food and Beverage Industry: In certain food and beverage processes where aggressive or acidic liquids need to be heated, Teflon-coated immersion heaters can be employed to prevent contamination and maintain the purity of the product. |

Semiconductor Manufacturing: Industries involved in semiconductor manufacturing often require precise temperature control for chemical processes. Teflon-coated immersion heaters can be used in such applications to ensure the integrity of the processes. | Petrochemical Industry: In petrochemical plants where the handling of corrosive liquids is common, Teflon-coated immersion heaters may be used for heating purposes. |

Plating Baths: Electroplating processes, which involve the immersion of objects into a plating bath, can benefit from coiled shape Teflon immersion heaters. The design helps in efficient and uniform heating of the bath. | Waste Treatment Facilities: Facilities dealing with the treatment of industrial waste containing corrosive substances might use Teflon-coated immersion heaters for maintaining specific temperatures during the treatment process. |

FAQ

1. Q: Contact Information:

R: Provide your company's name, address, contact person, email, and phone number.

2. Q: Project Overview:

R: Briefly describe the project or application where the coiled shape Teflon immersion heaters will be used. Include any specific requirements or challenges that the heaters should address.

3. Q: Technical Specifications:

R: Specify the technical requirements for the coiled shape Teflon immersion heaters, including:

Power rating (in kilowatts or watts).

Voltage and frequency requirements.

Coiled shape design details.

Dimensions (length, diameter, etc.).

Teflon coating specifications (thickness, temperature resistance, chemical compatibility).

Temperature control requirements (if any).

Any other technical specifications relevant to your application.

4. Q: Testing and Quality Assurance:

R: Before shipment, each heater is made to withstand pressure, insulation, and work in the sink for 1 hour.

5. Q: Compliance and Certification:

R: ISO9001:2015 and CE certification.

6. Q: Warranty:

R: 1 year.

| Applications: Our Plate Type Teflon Heater is ideally suited for single crystal texturing, cell texturing, and glass cleaning. | Product Information: Immersion Heater General Attributes: - Type: Immersion Heater - Power Source: Electric - Voltage: 110V-480V (can also be customized) - Brand Name: create - Condition: New - Place of Origin: Guangdong, China - Weight: 5 KG - Dimension (LWH): 350150 mm - Material: Plastic - Key Selling Points: Energy conservation by 20% - Application: Mainly used for preheating tank | |

Customization: We understand the diverse needs of our clientele. Hence, we offer customization based on various tank bodies, including voltage, power, specifications, and size | ||

Industry-Specific Attributes: - Applicable Industries: - Other - Food industry - Chemical industry - Electroplating industry | ||

Component Details: - Core Components: Heating wire with CPTFE - Material of Core Components: High-quality heating wire with CPTFE - Warranty of Core Components: 1 Year | Certifications & Inspections: - Machinery Test Report: Provided - Video Outgoing-Inspection: Provided | |

Warranty & Support: - Warranty: 1 Year | Packaging and Delivery: - Package Type: Packed with carton box, then packed in a wooden case - Supply Ability: 100 Piece/Pieces per Week | |

Lead time Quantity (pieces) 1 - 20 > 20 Lead time (days) 7 To be negotiated Samples Maximum order quantity: 1 piece Sample price: $500.00/piece |